Engineering Class Sprockets

Browse Tsubaki’s Engineering Class Sprockets, built to deliver accuracy and durability in demanding chain drive systems. Precision-machined and built for extended operational life, these sprockets are trusted by Canadian industries for reliability and performance.

Pair with our Engineering Class Chains for complete drive and conveyor chain solutions.

/Asset/engineering-class-sprockets-new-img.png

Sprocket and Traction Wheel Types

Tsubaki’s Sprockets and Traction Wheels are built for precision engagement and long-lasting durability in drive and conveyor systems. Engineered to handle heavy loads, they keep Canadian industries running smoothly.

See our complete range of Drive Chain Sprockets for additional power transmission solutions.

/Asset/Sprocket-Quotation-Request---Standard-Sprockets---Traction-Wheels.jpg

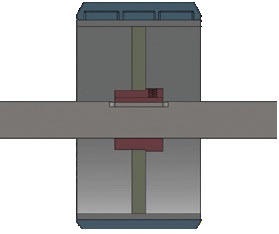

Drum Style Sprockets

"Optimize chain engagement with Tsubaki’s Drum Style Sprockets, designed for high-torque, low-speed conveyors. Engineered for durability and reliability, they provide dependable performance in heavy-duty Canadian industries.

Browse our full range of Drum Sprockets to complete your power transmission system.

Leverage the following data sheets to accurately document your sprocket for a quotation…

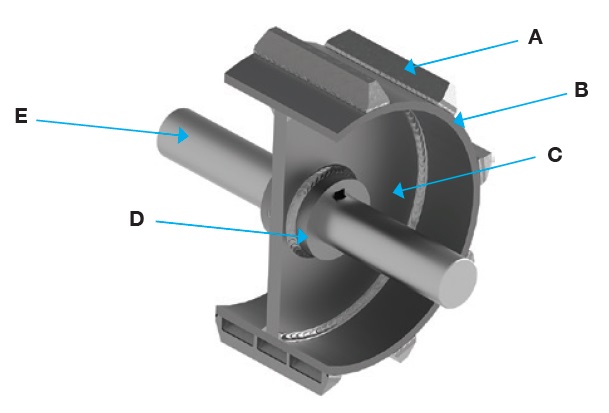

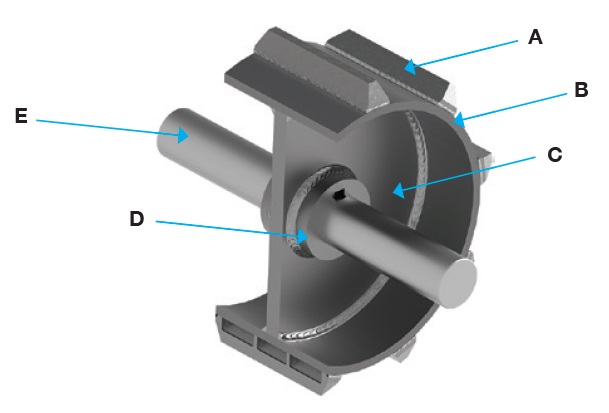

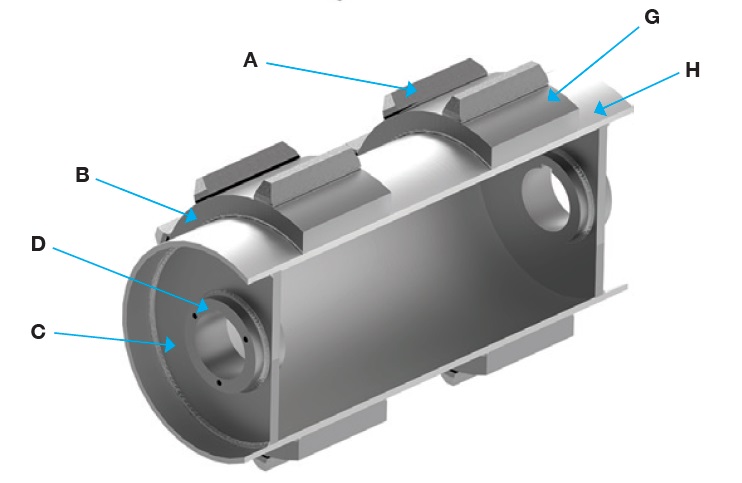

SINGLE DRUM SPROCKET

The Can is the main structural member of the drum assembly. Teeth are typically welded to the Can to provide positive traction, but traction wheel (toothless) style designs are also available.

A - Teeth

B - Can

C - Hub Plate

D - Hub

E - Shaft

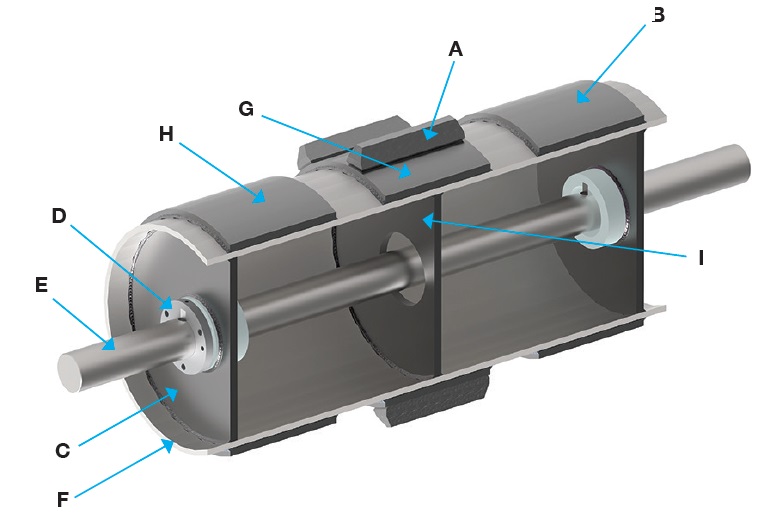

DOUBLE DRUM SPROCKET

Multi-strand drums are typically supplied with a Shroud. This allows for added strength and structural rigidity. Multi-strand drums without a Shroud are available upon request.

A - Teeth

B - Can

C - Hub Plate

D - Hub

G - Sprocket

H - Shroud

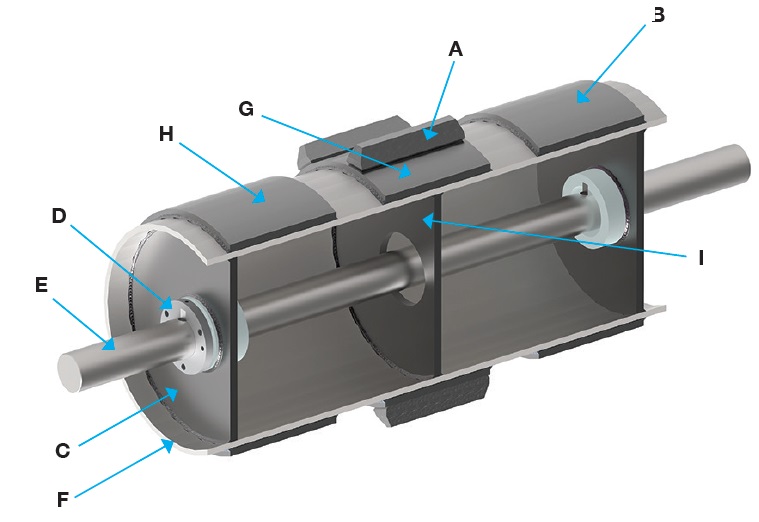

TRIPLE STRAND, COMBINATION SPROCKET & TRACTION WHEEL

Support Plates are utilized to provide additional structural rigidity and strength on triple strand drums and larger.

A - Teeth

B - Can

C - Hub Plate

D - Hub

E - Shaft

F - Shroud

G - Sprocket

H - Traction Wheel

I - Support Plate

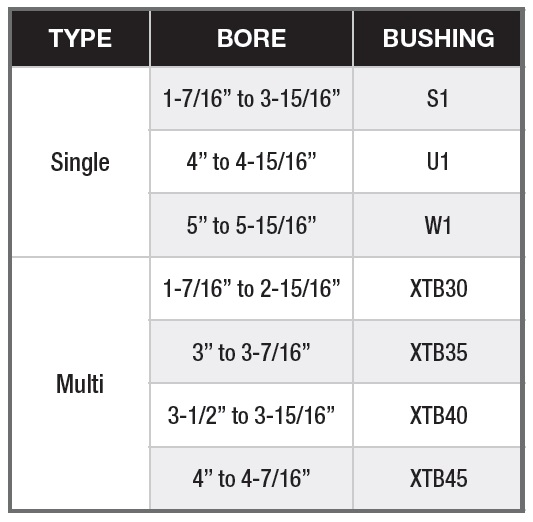

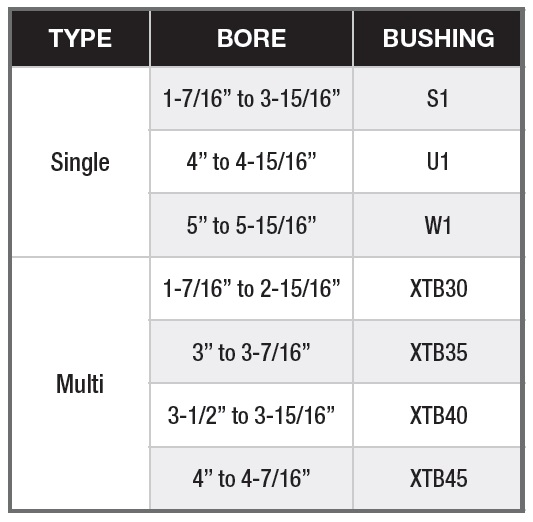

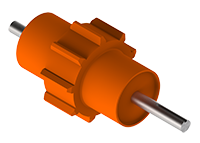

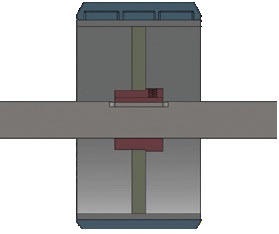

HUB STYLES

Style 1 for bores up to 3-15/16”.

Style 2 with double hub plates are required for bores greater than 4”. Split Taper bushings are standard for single style hubs.

Style 3 For ease of installation XTB type bushings are suggested for double hub construction.