Offset Sidebar Mill Chains

(21)Designed for shock resistance, Tsubaki’s Offset Sidebar Mill Chains provide dependable performance in mills, lumber yards, and aggregate conveyors. Built tough, they ensure long-lasting reliability in Canadian industries.

Browse more Welded Steel Mill Chains for heavy-duty applications.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

/Asset/Offset-Sidebar-Mill-Chains.jpg

Extra Heavy Duty Offset Sidebar Mill Chains

(10)Tsubaki’s Extra Heavy Duty Offset Sidebar Mill Chains handle extreme shock loads and abrasion in mill duty systems. Built for long service life, they’re trusted across Canada’s toughest industrial applications.

See more Welded Steel Mill Chains for severe-duty conveying solutions.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

Notes:

1/ WR: Offset sidebar style, with heat treated rivets.

2/ WH: Offset sidebar series, with all parts heat treated.

3/ WRXHD: Offset sidebar extra heavy duty series, with heat-treated rivets.

4/ WHXHD: Offset sidebar extra heavy duty series, with all parts heat treated.

5/ If extended wear life pin is required Tsubaki can supply IBR or IBRS as an option for all chain on this page.

6/ Riveted type connecting pins are supplied as standard cottered upon request.

Straight Sidebar Mill Chains

(8)Tsubaki’s Straight Sidebar Mill Chains resist fatigue and side loading in demanding conveyors. Designed for heavy-duty performance, they’re a reliable choice for Canadian mills and aggregate handling.

Explore additional Welded Steel Mill Chains for severe-duty configurations.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

/Asset/Straight-Sidebar-Mill-Chains.jpg

Extra Heavy Duty Straight Sidebar Mill Chains

(4)Engineered for reliability, Tsubaki’s Extra Heavy Duty Straight Sidebar Mill Chains deliver consistent alignment and fatigue resistance in demanding mill environments. Rugged and dependable, they support Canadian operations with strength.

Explore our Offset Sidebar Mill Chains for additional configurations.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

Notes:

1/ WRC: Straight sidebar style, with heat treated rivets.

2/ WHC: Straight sidebar series, with all parts heat treated.

3/ WRCXHD: Offset sidebar extra heavy duty series, with heat-treated rivets.

4/ WHCXHD: Straight sidebar extra heavy duty series, with all parts heat treated.

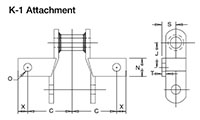

Offset Sidebar Mill Chains - K-1 Attachment

(9)With lateral stability for rugged conveyors, Tsubaki’s K-1 Offset Sidebar Attachment Chains ensure reliable alignment in abrasive environments. Trusted in Canadian mills, they deliver long-lasting performance.

Browse more Offset Sidebar Mill Chains for additional attachment options.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

Also available in WR

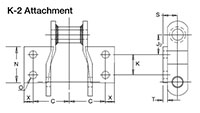

Offset Sidebar Mill Chains - K-2 Attachment

(10)Engineered for paired flight mounting, Tsubaki’s K-2 Offset Sidebar Attachment Chains provide strength in abrasive and heavy-duty mill applications. Built tough, they keep Canadian industries moving efficiently.

See related Offset Sidebar Mill Chains for more specialized solutions.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

Also available in WR

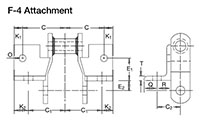

Offset Sidebar Mill Chains - F-4 Attachment

(5)Tsubaki’s F-4 Offset Sidebar Attachment Chains provide secure flight support in mill conveyors. Built for abrasive material handling, they deliver proven durability in Canadian operations.

See additional Offset Sidebar Mill Chains for a complete range of attachments.

One of the backbones of forestry operations, Welded Steel Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strenght. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates. Building upon the basic design, Tsubaki's Mill Chain Sidebars and Barrels are shot peened for additional fatigue strenght, Pins are precision fit for a superior press fit into side bar.

Also available in WR