Feeder Breaker Chains

Tsubaki Feeder Breaker Chains

Heavy-duty Feeder Breaker Chains from Tsubaki are designed to handle impact, fines, and high-load feeder applications. Built for mining and quarrying, they deliver proven reliability across Canadian operations.

Browse related Forged Mining Chains for underground material handling solutions.

Leveraging over a century of mining/aggregate conveying experience, Tsubaki is proud to offer a market leading portfolio of premium heavy duty feeder/breaker chains. These offerings are each uniquely designed to achieve ultimate durability, predictability and reliability in the most demanding feeder applications.

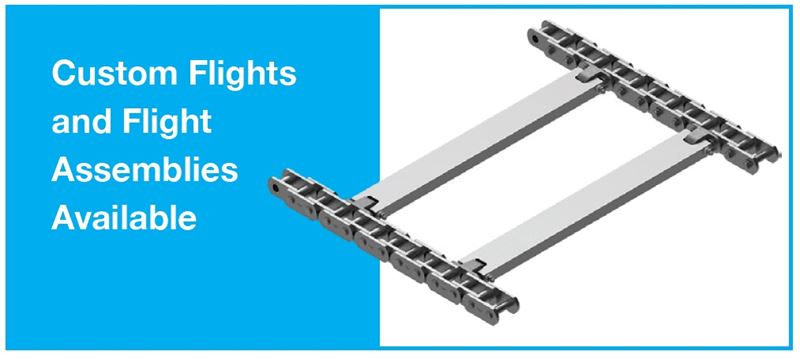

Custom Flights and Flight Assemblies Available

PINS

- Premium grade alloy steel.

- Heat treated for superior strength and toughness.

- Core – Through hardened for superior impact resistance.

- Surface – Induction hardened for extended wear resistance.

- Precision manufactured to maintain high interference fit with sidebars.

- Prevents pin rotation and subsequent sidebar wear.

BUSHINGS

- Premium alloy steel.

- Heat treated for superior strength.

- Core – Through hardened for toughness/impact resistance.

- Surface – Case hardened for ultimate/extended wear resistance.

- Precision manufactured to maintain high interference fit with sidebars.

- Favorable residual stresses resist fatigue and allow for extended life.

SIDEBARS

- Alloy or premium grade carbon steel.

- Through hardened for superior strength, toughness and fatigue resistance.

- Induction hardened sidebar edges are also available for extended wear resistance.

- Proprietary manufacturing processes ensure consistent hole quality and precise pitch control.

- High quality hole finish increases fatigue resistance.

TYPICAL APPLICATIONS

- Underground Feeder/Breakers

- Above Ground Feeders/Breaker

- Dozer Trap Style Feeders

- Submerged Flight Systems

COMMON INDUSTRIES

- INDUSTRIALS MINERALS

- MINING

- CEMENT

- FERTILIZER

- OIL & GAS

- POWER GENERATOR

Unit of Measure

| Items |

FB3067 Feeder Breaker Chains |

FB3075 Feeder Breaker Chains |

FB3035 Feeder Breaker Chains |

FB3040 Feeder Breaker Chains |

FB3500 Feeder Breaker Chains |

|||||

| Pitch | N/A 3.067 in | N/A 3.075 in | N/A 3.000 in3.500 in | N/A 3.000 in4.000 in | N/A 3.500 in | |||||

| Pitch1 | N/A 0 in | N/A 0 in | N/A 3.500 in | N/A 4.000 in | N/A 0 in | |||||

| Inside Width - A | N/A 1.56 in | N/A 1.31 in | N/A 1.88 in | N/A 1.88 in | N/A 2.25 in | |||||

| Bushing Diameter - B | N/A 1.50 in | N/A 1.25 in | N/A 1.50 in | N/A 1.50 in | N/A 1.75 in | |||||

| Pin Diameter - C | N/A 0.75 in | N/A 0.68 in | N/A 0.99 in | N/A 0.99 in | N/A 1.13 in | |||||

| Sidebar Height - D | N/A 2.25 in | N/A 1.5 in | N/A 2.5 in | N/A 2.5 in | N/A 2.75 in | |||||

| Sidebar Thickness - E | N/A 0.38 in | N/A 0.38 in | N/A 0.56 in | N/A 0.56 in | N/A 0.56 in | |||||

| Sidebar Thickness - E1 | N/A 0 in | N/A 0 in | N/A 0.50 in | N/A 0.50 in | N/A 0.50 in | |||||

| Pin Head to CL - F | N/A 1.72 in | N/A 1.63 in | N/A 2.28 in | N/A 2.28 in | N/A 2.47 in | |||||

| Pin End to CL -G | N/A 2.13 in | N/A 1.88 in | N/A 2.72 in | N/A 2.72 in | N/A 2.91 in | |||||

| Overall Width - H | N/A 3.84 in | N/A 3.50 in | N/A 5.00 in | N/A 5.00 in | N/A 5.38 in | |||||

| Average Ultimate Strength | N/A 141000 lb | N/A 69000 lb | N/A 160000 lb | N/A 160000 lb | N/A 164000 lb | |||||

| Max Working Load | N/A 7600 lb | N/A 4900 lb | N/A 10400 lb | N/A 10400 lb | N/A 13300 lb | |||||

|

|

||||||||||