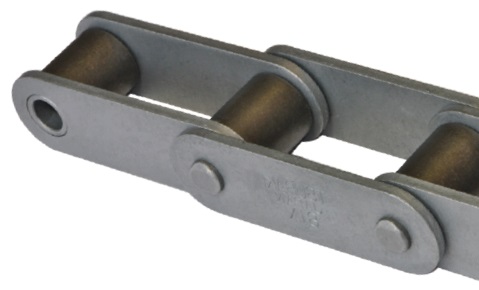

Roller Conveyor Chains - 1.654" to 5.000" Pitch

(20) Tsubaki’s Roller Conveyor Chain represents the most common and universal class of chain. Tsubaki is proud to offer a premium, well diversified portfolio designed and built in Sandusky, Ohio.PINS

- Alloy or premium grade carbon steel.

- Heat treated for superior strength and toughness.

- Core – Through hardened for superior impact resistance.

- Surface – Induction hardened for extended wear resistance.

- Precision manufactured to maintain high interference fit with sidebars.

- Prevents pin rotation and subsequent sidebar wear.

BUSHINGS

- Alloy or premium grade carbon steel.

- Heat treated for superior strength.

- Core – Through hardened for toughness and impact.

- Surface – Case hardened for the ultimate in extended wear resistance.

- Precision machined to maintain smooth bearing surfaces and high interference fit with sidebars.

- Favorable residual stresses resist fatigue and promote extended life.

SIDEBARS

- Premium carbon steel.

- Optional heat treated sidebars available.

- High quality hole finish increases fatigue resistance.

- Favorable residual stresses resist fatigue and allow for extended life.

ROLLERS

- Alloy or premium grade carbon steel.

- Through hardened for superior strength, toughness and the ability to withstand high shock loads.

TYPICAL APPLICATIONS

- Conveyors

- Elevators

- Power Transmission

- Unit/Material Transfer

- Assembly Conveyors

COMMON INDUSTRIES

AUTOMOTIVE

FOOD

METALS

GENERAL MANUFACTURING

SUGAR

ESCALATOR

/Asset/ROLLER-CONVEYOR-CHAINS---1-654-TO-5-000-PITCH--1-.jpg

Roller Conveyor Chains - 6.000" to 8.000" Pitch

(21)Tsubaki’s 6" to 8" Roller Conveyor Chains are designed for pallet, scrap, and material conveyors, delivering durability for medium-to-heavy duty cycles. Trusted across Canadian industries, they provide long-lasting performance.

See more Roller Conveyor Chains for complete chain drive integration.

Tsubaki’s Roller Conveyor Chain represents the most common and universal class of chain. Tsubaki is proud to offer a premium, well diversified portfolio designed and built in Sandusky, Ohio.

PINS

- Alloy or premium grade carbon steel.

- Heat treated for superior strength and toughness.

- Core – Through hardened for superior impact resistance.

- Surface – Induction hardened for extended wear resistance.

- Precision manufactured to maintain high interference fit with sidebars.

- Prevents pin rotation and subsequent sidebar wear.

BUSHINGS

- Alloy or premium grade carbon steel.

- Heat treated for superior strength.

- Core – Through hardened for toughness and impact.

- Surface – Case hardened for the ultimate in extended wear resistance.

- Precision machined to maintain smooth bearing surfaces and high interference fit with sidebars.

- Favorable residual stresses resist fatigue and promote extended life.

SIDEBARS

- Premium carbon steel.

- Optional heat treated sidebars available.

- High quality hole finish increases fatigue resistance.

- Favorable residual stresses resist fatigue and allow for extended life.

ROLLERS

- Alloy or premium grade carbon steel.

- Through hardened for superior strength, toughness and the ability to withstand high shock loads.

TYPICAL APPLICATIONS

- Conveyors

- Elevators

- Power Transmission

- Unit/Material Transfer

- Assembly Conveyors

COMMON INDUSTRIES

AUTOMOTIVE

FOOD

METALS

GENERAL MANUFACTURING

SUGAR

ESCALATOR

Roller Conveyor Chains - 9.000" to 18.000" Pitch

(16)Tsubaki’s Roller Conveyor Chain represents the most common and universal class of chain. Tsubaki is proud to offer a premium, well diversified portfolio designed and built in Sandusky, Ohio.

PINS

- Alloy or premium grade carbon steel.

- Heat treated for superior strength and toughness.

- Core – Through hardened for superior impact resistance.

- Surface – Induction hardened for extended wear resistance.

- Precision manufactured to maintain high interference fit with sidebars.

- Prevents pin rotation and subsequent sidebar wear.

BUSHINGS

- Alloy or premium grade carbon steel.

- Heat treated for superior strength.

- Core – Through hardened for toughness and impact.

- Surface – Case hardened for the ultimate in extended wear resistance.

- Precision machined to maintain smooth bearing surfaces and high interference fit with sidebars.

- Favorable residual stresses resist fatigue and promote extended life.

SIDEBARS

- Premium carbon steel.

- Optional heat treated sidebars available.

- High quality hole finish increases fatigue resistance.

- Favorable residual stresses resist fatigue and allow for extended life.

ROLLERS

- Alloy or premium grade carbon steel.

- Through hardened for superior strength, toughness and the ability to withstand high shock loads.

TYPICAL APPLICATIONS

- Conveyors

- Elevators

- Power Transmission

- Unit/Material Transfer

- Assembly Conveyors

COMMON INDUSTRIES

- AUTOMOTIVE

- FOOD

- METALS

- GENERAL MANUFACTURING

- SUGAR

- ESCALATOR

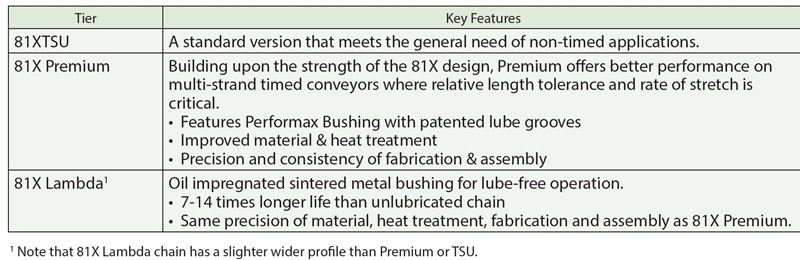

Roller Conveyor Chains - 81X Chain

(8)Built for strength and reliability, Tsubaki’s 81X Roller Conveyor Chains support lumber, packaging, and material flow conveyors. Their rugged design ensures dependable service in Canadian operations.

Explore additional Roller Conveyor Chains for a variety of pitch sizes.

ROLLER CONVEYOR STYLE AGRICULTURE GRADE CHAIN

81X STYLE - 2.609 PITCH

- Available in 81XTSU, 81XHDTSU, 81XHHTSU Carbon Steel Chain.

- Also available in 81XSSTSU Stainless Steel.

- 81XHDTSU and 81XHHTSU are both quad riveted pins for heavy side loading strength.

- All Tsubaki 81X chain have shot peened side plates for additional fatigue strength.

All 81X series chain can run on the same sprocket.

Features

81XTSU

A standard version that meets the general need of non-timed applications.

81X Premium

Building upon the strength of the 81X design, Premium offers better performance on multi-strand timed conveyors where relative length tolerance and rate of stretch is critical.

- Features Performax Bushing with patented lube grooves

- Improved material & heat treatment

- Precision and consistency of fabrication & assembly

81X Lambda

Oil impregnated sintered metal bushing for lube-free operation.

- 7-14 times longer life than unlubricated chain

- Same precision of material, heat treatment, fabrication and assembly as 81X Premium.

Note that 81X Lambda chain has a slighter wider profile than Premium or TSU.

Patented lube groove bushings standard on 81XPremium