Trimmer Lug Chains - 81X Chain

(7)Tsubaki’s 81X Trimmer Lug Chains provide strength and precision for timing-critical lumber operations. Built to an industry-standard profile, they deliver dependable service in Canadian sawmills.

Explore more Trimmer Lug Chains for additional chain styles and configurations.

Why choose one over the other? 81X is at the heart of every modern sawmill operation. This versatile chain is available in many grades of quality. At Tsubaki we are proud to offer three tiered levels of 81X quality:

81X Econo:

Features

An economical version that meets the general need of non-timed sawmill applications.

Applications

Non-Timed Conveyors:

- Transfers

81X Premium:

Features

Building upon the strength of the 81X design, Premium offers better performance on multi-strand timed conveyors where relative length tolerance and rate of stretch is critical.

- Improved material & heat treatment

- Precision and consistency of fabrication & assembly

Applications

Multi-strand Timed Conveyors:

- Scanner

- Trimmer

- Drop Sorter

81X Lambda:

Features

Oil impregnated sintered metal bushing for lube-free operation.

- 7-14 times longer life than unlubricated chain

- Same precision of material, heat treatment, fabrication and assembly as 81X Premium.

Applications

Multi-strand Timed Conveyors:

- Drop Sorter

- Trimmer

- Scanner

- Any application where contamination of the product must be avoided

Note that 81X Lambda chain has a slighter wider profile than Premium or Econo.

Trimmer Lug Chains - 81X Chain, 3939-B4

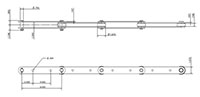

3939-B4 chain is an 8” pitch version of 81X chain and is used for lumber conveying. It is typically used in drop sorter applications. Lumber is conveyed using J-bar attachments on the chain. Tsubaki can install the J-bars on the chain. Tsubaki can also supply sprockets to work with 3939-B4 chain. Please contact Tsubaki Technical Support for more information. /Asset/Trimmer-Lug-Chains---81X-Chain--3939-B4.jpg

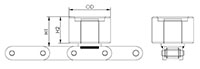

Trimmer Lug Chains - Roller Styl A

(3)Tsubaki’s Roller Style A Trimmer Lug Chains deliver smooth travel with reduced drag for trim line conveyors. Built for consistent lug movement, they provide long service life in Canadian sawmills.

Browse additional Trimmer Lug Chains for multiple lumber-handling solutions.

Trimmer Lugs are used to convey sawn wood through the scanner, trimmer and several other operations in a sawmill.

- Standardize operations and reduce inventory on replacement parts.

Note: Trimmer Lug will be welded on to the pin link or roller link depending on spacing requirements. Specify standard dimensions (OD or A) when ordering. Tsubaki also offers various sizes of trimmer lug weld-on attachments. Contact Tsubaki for more information.

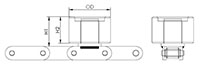

Trimmer Lug Chains - Roller Styl B

(3)Designed for high-speed sawmill conveyors, Tsubaki’s Roller Style B Trimmer Lug Chains provide minimal wear and dependable lug tracking. Trusted in Canadian lumber operations, they deliver reliable performance.

See our complete Trimmer Lug Chains range for lumber processing needs.

Trimmer Lugs are used to convey sawn wood through the scanner, trimmer and several other operations in a sawmill.

- Standardize operations and reduce inventory on replacement parts.

Note: Trimmer Lug will be welded on to the pin link or roller link depending on spacing requirements. Specify standard dimensions (OD or A) when ordering. Tsubaki also offers various sizes of trimmer lug weld-on attachments. Contact Tsubaki for more information.

Trimmer Lug Chains - Pusher

(2)Engineered for precise lumber positioning, Tsubaki’s Pusher-Style Trimmer Lug Chains ensure smooth handling and reliable transfer in wood processing operations across Canada.

See more Lumber Conveyor Chains for proven sawmill performance.

/Asset/Trimmer-Lug-Chains---Pusher_2.jpg

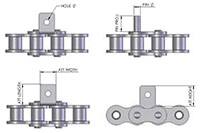

Standard Attachment Chain

Engineered for versatility, Tsubaki’s Standard Attachment Chains are built for mounting brackets and fixtures in packaging and material handling conveyors. Reliable and durable, they support Canadian industries with proven performance.

Browse more Attachment Chains for rugged, application-specific solutions.

To order attachment chain, please provide the following:

1) Size of chain (40, 50, C2062H)

2) Material

3) Rivet or Cotter Pin construction

4) Type of attachment

5) Spacing of attachment

- Attachment spacing is counted as being the number of links (both inside and outside) up to and including the next attachment. In the non-standard spacing example to the right, initial spacing is every 2nd (2L) and then every 4th (4L). Each repeating section is 8 pitches (8L).

6) Overall length of chain

ASME (ANSI) Special Attachments

In addition to providing standard attachment chain, Tsubaki of Canada can modify existing attachments to match your requirements.

An example of this could be a shorter-than-standard pin or a larger hole diameter. If modifying standard attachments, delivery can be 1-2 weeks depending on the quantity.

When specifying non-standard attachments, information required is:

- tab length, width and possibly height

- hole diameter and type of hole (threaded, countersunk)

- pin diameter, projection (extension) length, type of end (threaded, circlip groove)