Tsubaki’s new BS-F Series backstops are designed for simple, drop-in installation to all major competitive external, low-speed backstop products. These backstops use a unique labyrinth seal design for maximum life with minimal maintenance. With Tsubaki’s innovative design features, our backstops ensure efficient and dependable operation in the harshest environments.

TYPICAL APPLICATIONS

- Mining (Coal, Copper, Potash) - used in inclined conveyors and bucket elevators for transporting raw materials.

- Power Generating Plants - used in inclined conveyors to transfer coal from the stockpile to the boiler rooms.

- Cement Plants - used in bucket elevators and inclined conveyors for moving limestone and clay to crushers and silos.

COMMON INDUSTRIES

MINING

POWER GENERATING PLANTS

CEMENT

PORTS

INNOVATIVE FEATURES:

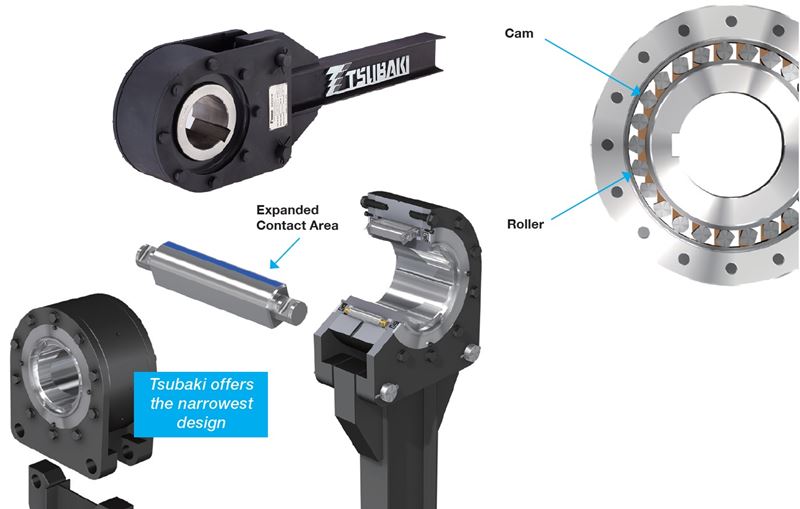

NON-ROLLOVER CAM

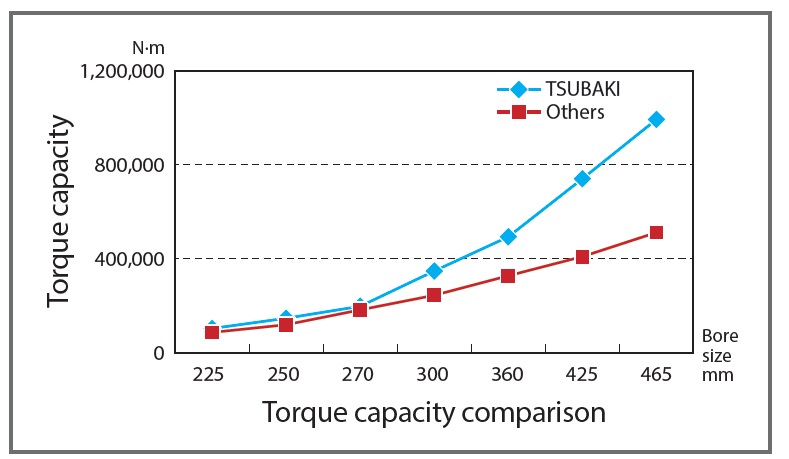

- Provides higher torque ratings than the leading competitors due to the larger profile and greater contact area.

- Improves performance and prevents costly and potentially dangerous rollover.

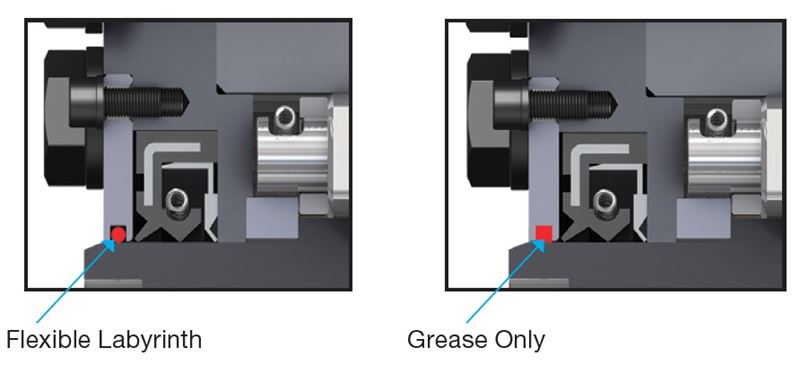

SPECIAL LABYRINTH SEAL

- New seal design prevents the ingress of dust and other contaminants typically found in mining and cement plants, which extends the life of the lubricant.

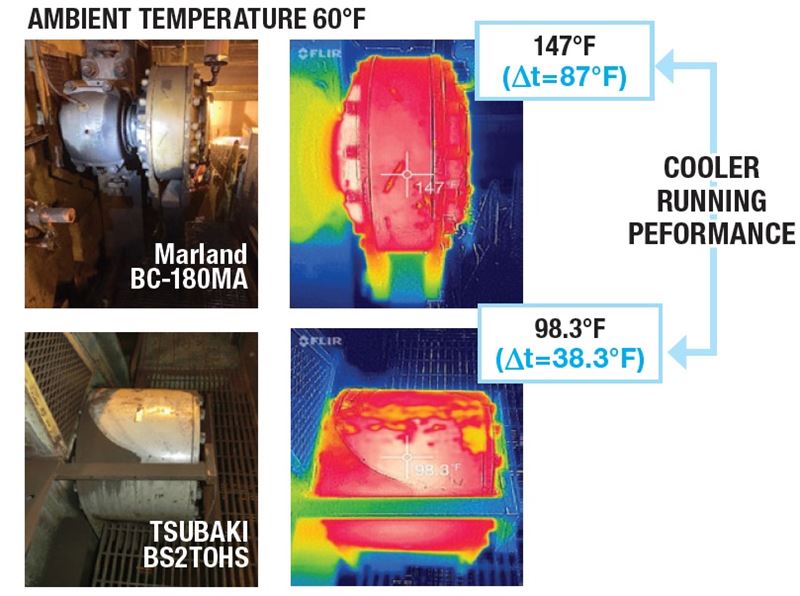

- Minimizes heat generation and provides trouble-free service with minimal scheduled maintenance.

Superior Performance in the Harshest Environments

GREASE LUBRICATION

- Offers synthetic grease lubrication in a sealed backstop design.

- Breather element is eliminated.

- No need to monitor oil levels, refill the backstop or worry about moisture in the lubricant.

- Provides trouble-free performance with minimized maintenance requirements.

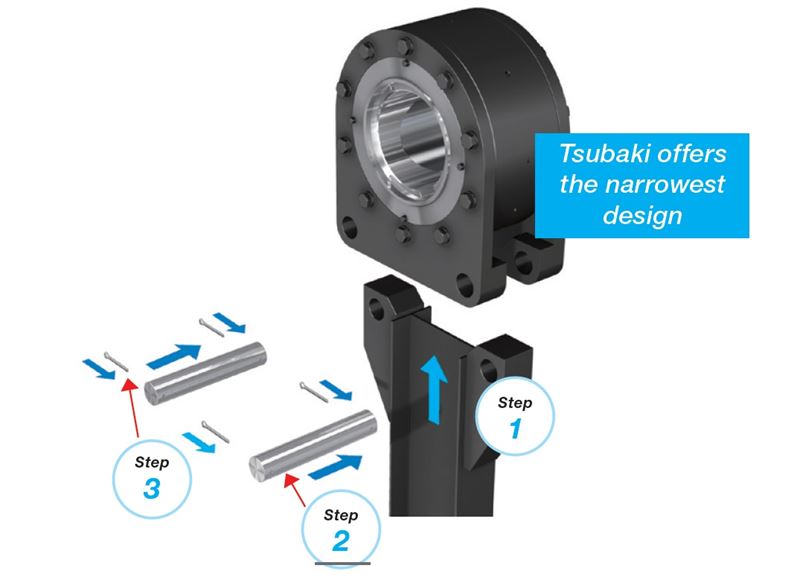

DROP IN DESIGN

- Tsubaki offers the narrowest backstop with an I-beam torque arm.

- Quick and easy field replacement. Drop in compatible with most competitive products.

3 STEP

EASY CONNECTION

Step 1: Insert I-beam torque arm into clutch

Step 2: Insert lock pins through flange plate and secure torque arm

Step 3: Insert retaining pins into lock pins

Specifications

Bore Range - Max. |

N/A 10.630 in270.00 mm |

Bore Range - Min. |

N/A 7.870 in200.00 mm |

Torque Capacity |

N/A 141000 lb·ft192000 N·m |

Inner Race Max. Overrunning Speed |

N/A 125 rpm |

Drag Torque |

N/A 72.220 lb·ft98.00 N·m |

A - Backstop width |

N/A 10.510 in267.00 mm |

B - Overall length |

N/A 25.590 in650.00 mm |

C - Inside width |

N/A 10.000 in254.00 mm |

D - Center line of backstop to flange edge |

N/A 16.340 in415.00 mm |

E - Counterbore inside diameter |

N/A 13.540 in344.00 mm |

F - Overall inner race width |

N/A 11.020 in280.00 mm |

G - Counterbore depth |

N/A 0.510 in13.00 mm |

H - Overall backstop width |

N/A 11.930 in303.00 mm |

J - Distance from backstop center line to I-beam edge |

N/A 87.990 in2235.00 mm |

K - Torque arm height |

N/A 12.010 in305.00 mm |

L - Torque arm width |

N/A 5.510 in140.00 mm |

Amount of grease |

N/A 3.520 lb1.600 kg |

Weight - With Torque Arm - Min. Bore |

N/A 1955.800 lb889.000 kg |

Weight - With Torque Arm - Max. Bore |

N/A 1821.600 lb828.000 kg |

Weight - Without Torque Arm - Min. Bore |

N/A 1522.400 lb692.000 kg |

Weight - Without Torque Arm - Max.. Bore |

N/A 1388.200 lb631.000 kg |